VACUUM METALLIZING

Vacuum metallizing creates a one-way mirror or reflective effect on the part. Metallizing is compatible with thermoformed or injection molded parts in acrylic, polycarbonate, or nylon. A mirrored coating provides the best method for concealment. For instance, in security applications, the mirrored coating conceals the camera, but does not interfere with the camera’s function. Metallized parts are available in 24KGold or 420 stainless ‘chrome’ finish. Other custom coatings are available upon request either through Criterion’s metallizing process or specialized partners.

PAINT

Criterion Technology offers in-house painting services designed to streamline production and reduce time to market. We provide custom painting in a wide range of colors and finishes, all tailored to meet the specific branding or functional requirements of our customers. Whether it’s a matte black for a sleek security device or a custom-matched color for OEM consistency, our paint capabilities ensure precision and durability. By integrating painting directly into our production process, we enable customers to receive fully finished components, reducing the need for secondary suppliers and allowing Criterion to deliver fully assembled, paint-finished products that are ready for final integration. This vertically integrated approach improves quality control, reduces lead times, and simplifies supply chain coordination.

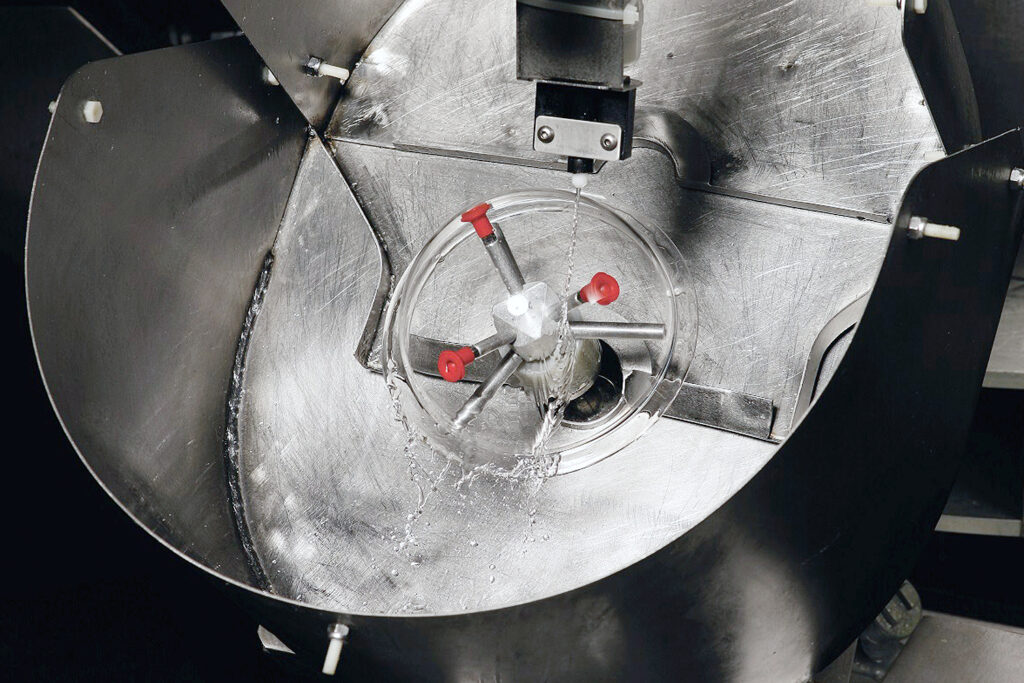

ELECTROSTATIC DISCHARGE

The same partners that helped develop the scratch resistant coating also developed an electrostatic discharge (ESD) coating for highly sensitive applications. Using the same custom built machines, the ESD coating is applied to the exterior of polycarbonate injection molded parts to dissipate any static charge. Other coatings are available through Criterion’s partners, for example, reflective/anti-reflective (AR) and ITO conductive coatings on shallow draw or flat windows.